Comprehensive Guide to T Patti Profiles, T Profiles, and Stainless Steel T Patti

T profiles, T patti, T patti profile, T patti size, T profile, Stainless steel t patti, SS t patti, Stainless steel t profile, SS t profile, T patti

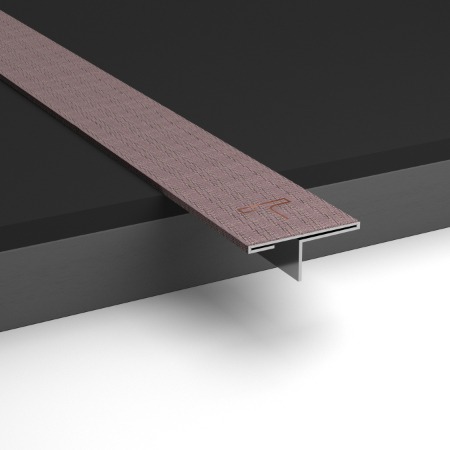

In the construction and interior design industry, T Patti profiles and T Profiles play a pivotal role. Whether it’s the sleek finish of stainless steel or the robust build of SS T Patti, these components are essential for ensuring both structural integrity and aesthetic appeal. This article aims to provide an in-depth look at T Patti profiles, their sizes, materials, and applications, ensuring you have all the information needed to make informed decisions.

What are T Patti Profiles and T Profiles?

T Patti profiles, often referred to simply as T profiles, are structural components used primarily in construction and interior design. They are shaped like the letter “T” and serve various purposes, including edging, framing, and reinforcing structures. These profiles are made from different materials, with stainless steel being one of the most popular due to its durability and resistance to corrosion.

Types of T Patti Profiles

There are several types of T Patti profiles available in the market, each catering to different needs:

- Standard T Patti Profiles: These are the most commonly used profiles, suitable for general construction purposes.

- Heavy-Duty T Patti Profiles: Designed for applications requiring extra strength and durability.

- Decorative T Patti Profiles: Used primarily in interior design for aesthetic purposes, available in various finishes and materials.

Importance of T Patti Size in Construction

The size of T Patti profiles is a crucial factor in their application. The dimensions of these profiles determine their load-bearing capacity and suitability for different uses. Standard sizes vary, but custom sizes can be manufactured to meet specific project requirements.

Common T Patti Sizes

- Small T Patti Profiles: Ideal for lightweight applications and detailed finishing work.

- Medium T Patti Profiles: Suitable for general construction and interior design projects.

- Large T Patti Profiles: Used in heavy-duty construction where higher load-bearing capacity is required.

Material Choices for T Patti Profiles

Material selection for T Patti profiles significantly affects their performance and longevity. The most common materials include:

Stainless Steel T Patti

Stainless steel T Patti is renowned for its superior strength, resistance to rust, and long-lasting finish. It is ideal for both indoor and outdoor applications, especially in environments exposed to moisture and corrosive elements.

SS T Patti

SS T Patti (Stainless Steel T Patti) shares the same properties as stainless steel but is often referred to in industries that emphasize high precision and quality standards. It is preferred in applications where aesthetics and performance are equally important.

Aluminum T Patti

Aluminum T Patti is lightweight and resistant to corrosion, making it suitable for applications where weight is a concern without compromising on strength.

PVC T Patti

PVC T Patti profiles are used in applications requiring flexibility and easy installation. They are popular in interior design for edging and decorative purposes.

Applications of T Patti Profiles

T Patti profiles have a wide range of applications across various industries. Here are some of the most common uses:

Construction Industry

In construction, T Patti profiles are used for reinforcing structures, providing support to walls, ceilings, and floors. Their robust design ensures that buildings can withstand significant stress and loads.

Interior Design

In interior design, T Patti profiles add a touch of elegance and sophistication. They are used for framing, edging, and as decorative elements that enhance the overall aesthetics of a space.

Automotive Industry

In the automotive industry, T Patti profiles are used in vehicle manufacturing for structural support and reinforcement. Their lightweight and durable nature make them ideal for this purpose.

Furniture Manufacturing

T Patti profiles are also used in furniture manufacturing, providing both structural integrity and decorative appeal. They are often used in the construction of modern and contemporary furniture pieces.

Benefits of Using Stainless Steel T Patti

Using stainless steel T Patti offers several advantages:

- Durability: Stainless steel is incredibly durable and can withstand significant wear and tear.

- Corrosion Resistance: It is resistant to rust and corrosion, making it suitable for various environments.

- Aesthetic Appeal: Stainless steel has a sleek, modern look that enhances the appearance of any application.

- Low Maintenance: It requires minimal maintenance, reducing long-term costs.

Choosing the Right T Patti Profile for Your Project

Selecting the right T Patti profile involves considering several factors, including the application, load requirements, and environmental conditions. Here are some tips to help you make the right choice:

- Assess the Load Requirements: Determine the load-bearing capacity needed for your project and choose a profile that meets or exceeds these requirements.

- Consider the Environment: If the profile will be used in a corrosive environment, stainless steel or SS T Patti is the best choice.

- Aesthetic Considerations: For projects where appearance matters, opt for decorative T Patti profiles with the desired finish.

- Budget Constraints: While stainless steel offers numerous benefits, it can be more expensive. Consider your budget and choose the best material that fits within it.

Conclusion

T Patti profiles and T Profiles are essential components in various industries, offering both structural support and aesthetic enhancement. Whether you opt for stainless steel T Patti, SS T Patti, or another material, these profiles provide unmatched durability and versatility. By understanding the different types, sizes, and materials available, you can make informed decisions that ensure the success of your projects.