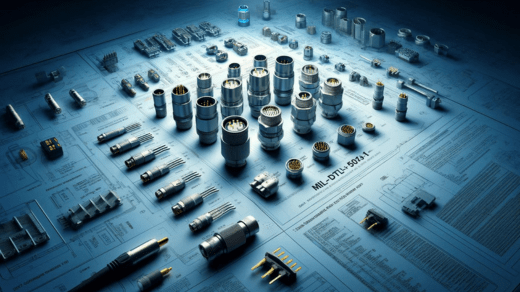

A Brief Overview Of Mil Dtl 5015 Connectors: Types And Specifications

Multipin military connectors, MG connectors, MS connectors, Mil grade connectors, Mil dtl 5015 connectors

As one of the most reliable workhorses in the electrical connector world, Mil DTL 5015 connectors are recommended for military and aerospace applications. These connectors aim to meet the stringent requirements of durability, performance, and versatility. Let’s look at the types and specifications of connectors to understand their importance.

1. The Essence Of Military Connectors

Mil DTL 5015 connectors, often called MG connectors or MS connectors, are widely recognised for their robust design and suitability for harsh environments. Due to their ability to withstand extreme conditions like moisture, vibration, and temperature variations, they are classified as mil-grade connectors.

2. Variants And Features

MIL connectors come in types, each tailored to specific needs.

- Standard Circular Connector: These connectors are known for their circular design, providing a compact and reliable solution for multi-pin military connectors. They are available in many sizes and configurations to accommodate various application requirements.

- Environmentally Sealed Connectors: Designed with environmental sealing, these connectors protect against dust, moisture, and other contaminants.

- Hermetic Connectors: Some Mil DTL 5015 connectors are designed with hermetic sealing, ensuring a completely airtight and watertight connection. These connectors are critical in applications where it is necessary to maintain a controlled environment free of external contaminants, such as aerospace, medical devices, or underwater systems.

3. Specifications And Performance

Mil DTL 5015 connectors adhere to stringent military specifications to ensure consistent quality and performance. Some key specifications include:

- Voltage And Current Rating: These connectors are rated to handle specific voltages and currents, allowing safe and reliable power transmission.

- Materials And Coatings: these connectors aim for durable materials such as aluminium or stainless steel with corrosion-resistant coatings to increase longevity.

- Temperature And Environmental Rating: The connectors aim to operate in a wide temperature range from -55°C to 125°C, making them suitable for operating environments.

- Reverse Bayonet Coupling Connectors: These connectors feature a reverse bayonet coupling mechanism, which provides a safe and quick mating process. The connectors are suitable for demanding applications in military vehicles, industrial machinery, and telecommunications equipment due to their superior durability and vibration resistance provided by the reverse bayonet design.

4. Applications In Defense And Beyond

There is no industry where Mil DTL 5015 connectors are not indispensable due to their versatility and robustness.

- Industrial Machinery: connectors are used in heavy machinery, industrial automation, and robotics, where reliability and durability are paramount.

- Transportation: these connectors are employed in rail transportation, ensuring secure connections to signalling and control systems.

- Substations, Energy Sector: these connectors play an important role, especially in power generation and distribution. These connectors aim to facilitate secure connections to control systems, sensors, and monitoring equipment in power plants, substations, and renewable energy installations. Their durability and resistance to environmental factors make them ideal for resisting the challenges of power generation environments.

Conclusion

Mil DTL 5015 connectors’ ability to endure harsh environments and stringent specifications makes them a top choice for critical applications in defence, aerospace, and other industries. To access the widest selection of connectors and superior interconnect solutions, explore the offerings from various suppliers, such as Allied Electronics Corporation.